USBF (Upflow Sludge Blanket Filtration) monoblock integrated reactor

The principal of separation by filtration of suspended solids of biological sludge applied in USBF technology is much more efficient, compared with sedimentation.

This efficiency manifests itself in two major ways, by high separation efficiency which results in higher treated water quality and by higher separation velocity, enabling the reduction of the size of the USBF separator. The volume of the USBF separator is only 1/4 compared with the volume of the sedimentation basin which enables to incorporate the USBF separator into the activation basin of the biological treatment unit, providing a monoblock solution of the whole wastewater treatment plant.

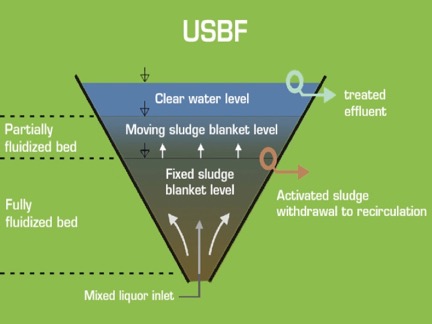

Principle of USBF technology

Advanced USBF system for wastewater treatment plants employs the technology of low loaded biological activation process with nitrification/ de-nitrification

Activated sludge separation from mixed liquor is accomplished by up-flow

sludge blanket filtration (USBF)

All treatment and sludge separation processes are combined within the compact Integrated USBF Reactor

During treatment, the suspended activated sludge is repeatedly exposed to nitrifying and denitrifying conditions

Low sludge loading combined with repeatedly changing oxic and anoxic conditions within the bioreactor internal closed circulation loop and the incorporation of a biological selection action (mechanically pretreated wastewater first enters anoxic compartment of the bioreactor), results in the formation of a very specific biocenosis in the activated sludge

3 examples of installed systems (total number over 500)

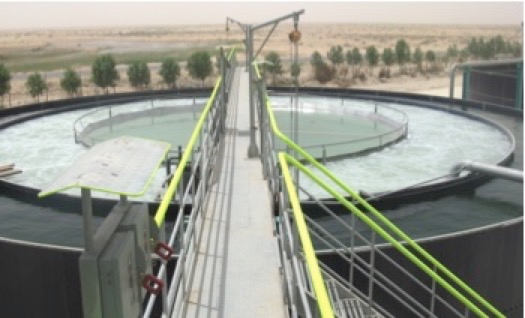

Juabail, Saudi Arabia, (5000 PE)

Kedainai, Lithuania (42000 PE)

Rokiskis, Lithuania (20000 PE)